Some references for the reconditioning and modernization of machine tools:

HELLWIG commands extensive experience with these types of machines:

CNC lathes, coordinate boring machines, copying lathes, cylindrical grinders, centerless grinders, cycle lathes,

front-operated and facing lathes,

gear cutters,

horizontal boring machines, horizontal milling machines,

lathes,

machining centers, measuring machines,

planing machines, plano-milling machines,

portable boring and milling machines, portal milling machines, profile grinders,

radial drills, roll grinding machines, roll-turning lathes,

special machines, surface grinders

toolroom milling machines, turret lathes,

vertical boring and turning mills

A partial listing of the most important manufacturers and brands that HELLWIG is familiar with:

Aba, Alpha,

Blohm, Boehringer, Bohner&Köhle, Böhringer, Brinkmann, Buderus,

Cazeneuve, Chiron, Churchill, Cinncinati, Colchester, Correa,

De Vileg, Deckel, Dixie, Donau, Droop&Rein,

Emag,

Fluri, Fortuna, Fritz Werner, Froriep,

Georg Fischer, Gildemeister, Grazianer,

H&H, Hauser, Heckert, Heller, Hermle, Hessap, Heyligenstedt, Hirscheider, Hüller, Hille, Huron,

Jung, Jungental,

Kehren, Kellenberger, Klink, Klopp, Kolb, Köllmann, Kopp,

Lidköpping, Loewe,

Maho, Maka, Makino, Mammut, Martin, Max Müller, Mecof, Mengele, Mikron,

Niles,

Oerlikon, Okuma, Overbeck,

Rambaudi, Ravensburg, Reckermann, Reishauer,

Saakmann, Sacem, Schandt, Scharmann, Schaudt, Schiess, Secmu, Sip, Stama, Steinel, Stiefelmaier,

TOS, Traub,

Union,

VDF,

Waldrich, Wanderer, Weiler, Weisser, Witt, Wotan, Wysbrod,

And many others

Restoration of the geometric precision of a Pfauter hobbing machine

- Restoration of the geometric precision

- including new finish

Modernization of a Schmaltz slideway grinding machine, type RVU

- Restoration of the geometric precision in accordance with DIN standards

- Modification of lubrication systems

- Modification of feed drive

- Modification of table drive

- Modification of grinding spindle head on motor-driven grinding spindle

- New drives

- Controller modernization including new PLC in the required expansion stages

- Renewal of the switch cabinet and complete machine cabling

- Use of safety controller

- Renewal of primary/secondary enclosure

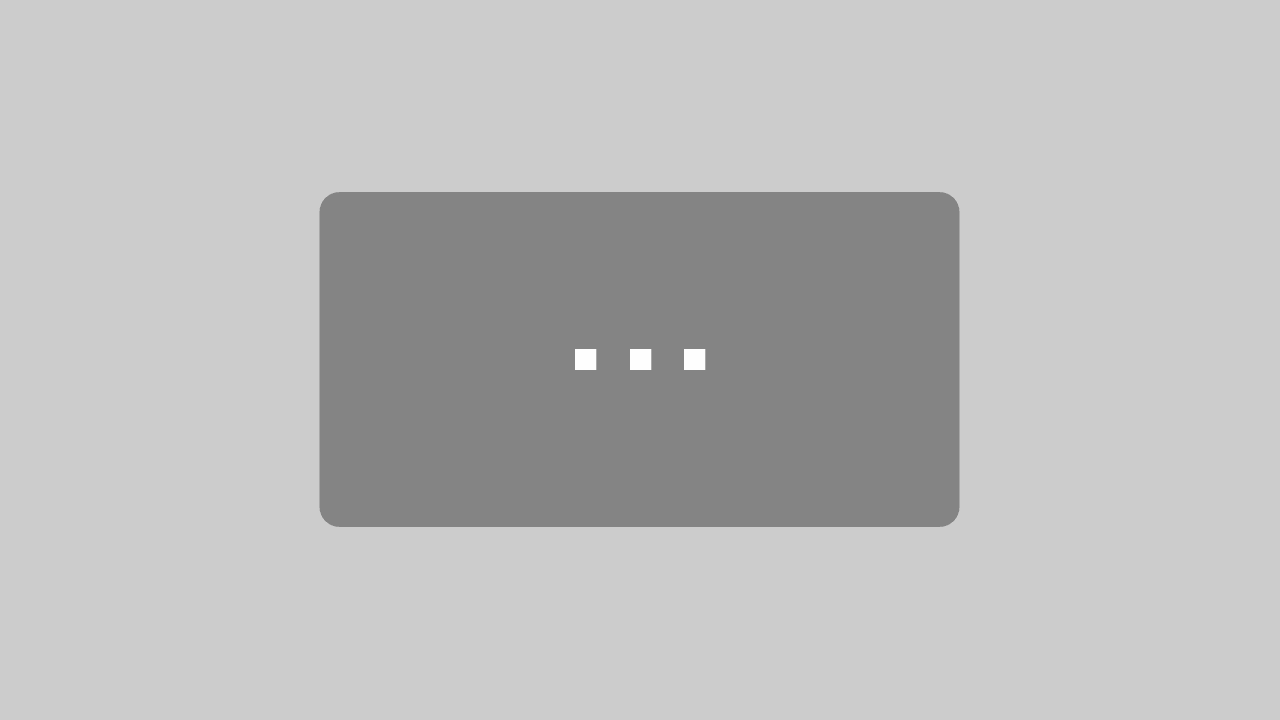

Geometric reconditioning and repair of a gear cutting machine.

- Overhauled extensively

- Geometric DIN standard

- new electrics with SPS

- Distance between centers 16,000 mm,

- Swing/diameter turned 1600 mm

- Including new electrical equipment and PLC control

Geometric reconditioning and repair of an L. Z. lathe from Heidenreich & Harbeck, type Hamburg 540.

- Geometric reconditioning and modernization

- Equipping with CNC control

- Siemens 840 D

- Use of a self-centering chuck with electronically adjustable clamping pressure

- Use of a distance, time and axis-dependent central lubrication system

- Use of an electro-pneumatic ratchet adjustment on the tailstock

- Conversion of the tailstock hand clamping to hydraulic clamping with 20 t clamping power.

CNC lathe – Gildemeister, type N.E.F. CT 20

Geometric reconditioning and repair of a CNC lathe – Gildemeister, type N.E.F. CT 20 including

- Purchase and attachment of a gripping device

- Purchase and attachment of a chip conveyor

Cylindrical grinder – Naxos, type R 500 / 3500

Geometric reconditioning and modernization of a machine from Naxos, type R500/3500 including

- Repair of mechanics and hydraulics

- Modernization of the electronic equipment

- Modernization of the machine installation

- Painting of the machine

- Geometric reconditioning with the result: “The machine grinds like a new machine, perhaps even better …”

- Mechanical reconditioning and modernization of the milling machines for workpieces with individual weights up to 100 to.

- With complete controller conversion.

- Only 7 weeks machine standstill instead of 9 months delivery time, including the time for commissioning for a new machine many times more expensive