HELLWIG offers you complete service for your special machine(s)

Working closely with you, we check all expedient ways of realizing your special machine project. This process also includes everything from joint feasibility studies to the procurement of a suitable basic machine in the event that you do not already own one.

Thanks to its longstanding international contacts, HELLWIG is able to procure a suitable machine for you on the global market. If you also want an appraisal and purchase consultation at the site, we accompany you to the location of the machine that you want and back you up with competent advice.

Contact us if you are planning a (conversion to a) special machine.

You can view some current examples here:

Conversion of a vertical boring and turning mill from SEDIN, table diameter: 2800 mm

- Design and manufacture of new vertical slides with CNC-controlled 4-way tool holders

- Design and manufacture of new longitudinal slides

- Combined linear slideways for the X-axes

- Conversion of the main gearbox to an adjustable gearbox (V-constant)

- Installation of an automatic crossbar clamp

- Completely new hydraulic system

- New table with hydrostatic table bearing including automatic workpiece fixture

- Geometry in accordance with DIN

- New electrical equipment with Siemens 840 D CNC

- Documentation

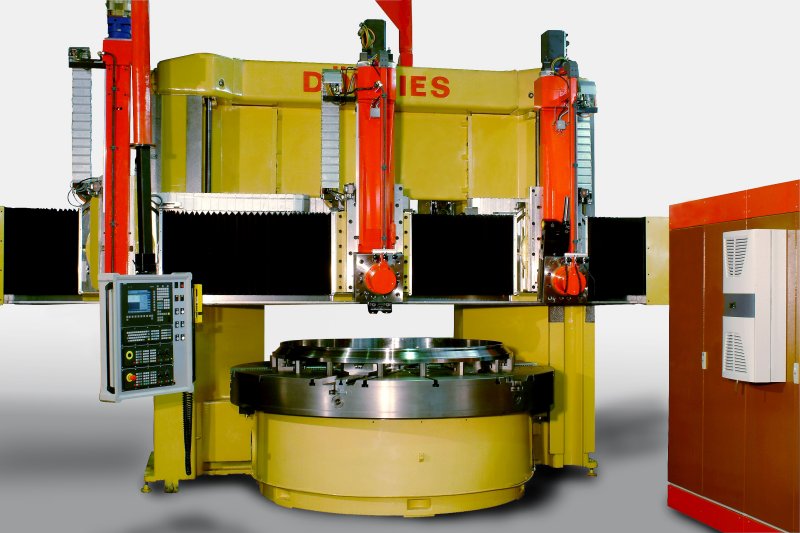

Conversion of a vertical boring and turning mill from Dörries, table diameter: 2800 mm

- Geometry in accordance with DIN

- Mechanical reconditioning

- Design and manufacture of a second machining unit to reduce the manufacturing time

- Conversion of the right turning station to single-axis drive

- Design and manufacture of 4-way head-type turrets

- Conversion of the drilling and milling spindle unit

- Conversion of the drilling and milling spindle gearbox

- Conversion of the main gearbox to an adjustable gearbox (V-constant, S1 spindle, rotary table with positioning)

- Completely new hydraulic system

- Automatic central lubrication system

- New electrical equipment with Siemens 840 D CNC

- Documentation

Conversion of a CNC vertical boring and turning mill from Schiess Froriep, table diameter 3500 mm

- Geometry in accordance with DIN

- Mechanical reconditioning

- Conversion of the railhead to milling drive including milling head and pick-up station

- Manufacture and installation of a chip and splash guard cover

- Manufacture and installation of a stationary machine operator lifting platform with type test and acceptance by an EU expert

- New electrical equipment with Siemens 840 D CNC

- CE consultation and marking for the machine as a whole

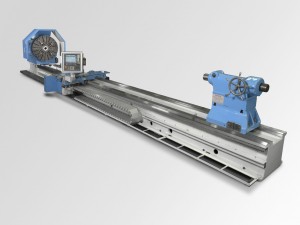

Modernization and conversion of a deep-hole boring machine from Froriep, machining length 22000 mm

- Geometry in accordance with DIN

- Design and manufacture of a headstock

- Design of master-slave 4-way drive with a total of 10 to feed force

- Design and manufacture of new bed segments to a total of 25000 mm

- Reconditioning/conversion measures on sliding drill heads and boring bar guide bearing

- Time-regulated central lubrication system

- New electrical equipment with Siemens 840 D CNC

- CE consultation and marking for the machine as a whole

- Documentation

Conversion of a vertical boring and turning mill from SEDIN, table diameter 4000 mm

- Design and manufacture of new vertical slides with CNC-controlled 4-way tool holders

- Design and manufacture of new longitudinal slides

- Combined linear slideways for the X-axes

- Conversion of the main gearbox to an adjustable gearbox (V-constant)

- Installation of an automatic crossbar clamp

- Completely new hydraulic system

- New table with hydrostatic table bearing including automatic workpiece fixture

- Geometry in accordance with DIN

- New electrical equipment with Siemens 840 D CNC

- Documentation

Modernization and conversion of a Wohlenberg W 57 lathe

- Design and manufacture of a no-play feed gear mechanism (master-slave)

- Conversion of the main gearbox to V-constant within 4 switching stages

- Conversion of the radial facing slide to position-controlled single-axis adjustment

- Retrofit of a brake system for the lathe spindle (C-axis)

- Time-regulated central lubrication system

- Design and attachment of a protective device for the table

- New electrical equipment with Siemens 840 D

- Documentation